Case Study:

Shortage Management

Initial Situation

- Severe shortages of key components due to the global semiconductor crisis

- Overloaded customer order backlog

- Rapid rise in risk of unfulfillable delivery commitments

- Inventory increase due to customer pushouts & cancellations

- Unreliable customer forecasts; risk of duplicate or inflated orders

- Cash flow pressure from growing inventory levels

Actions & Approach

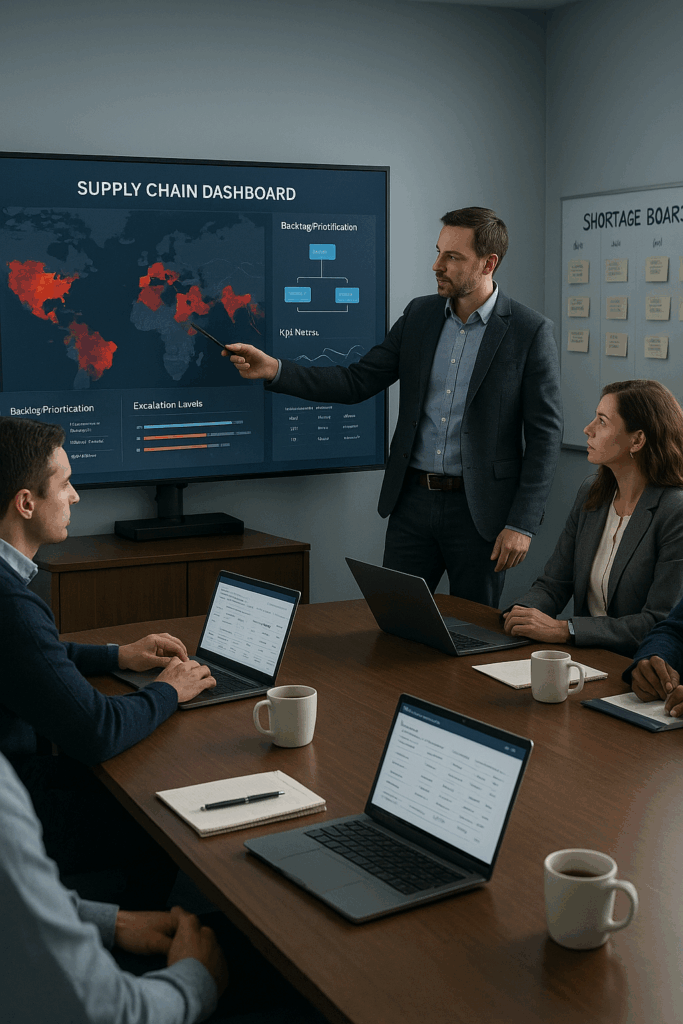

Shortage Management & Escalation Framework

1. Backlog & Forecast Screening

- Systematic assessment and prioritization of open customer orders

- Close coordination with customers to eliminate phantom demand

- Clear communication of “No Cancel / No Reschedule” (NCNR) terms

2. Shortage Steering & Escalation Process

- Established a dedicated “Shortage Board”

- Leveraged global supplier contacts

- Structured evaluation of lead times and confirmed quantities

3. KPI-Based Management & Early Warning Systems

- Developed and launched a backlog dashboard

- Integrated metrics: On-Time Delivery, Purchase order backlog status, Customer requested vs confirmed date ratios

- Defined escalation levels

4. Tight Collaboration with Sales & Customers

- Weekly joint risk reviews with key customers

- Regular analysis of inventory KPIs

- Introduced a “Demand Transparency Framework”

Results & Impact

- Reduced purchase order backlog

- Improved availability for prioritized components

- Restored transparency and credibility with both customers and suppliers

- Established a lasting early warning system

- Defined a scalable escalation process