Case Study:

Supplier Management

Initial Situation

- Supplier performance only selectively and subjectively

- High strategic dependence on key suppliers

- No standardized approach

- Lack of comparability across functions

- Need for transparency to drive improvements

Actions & Approach

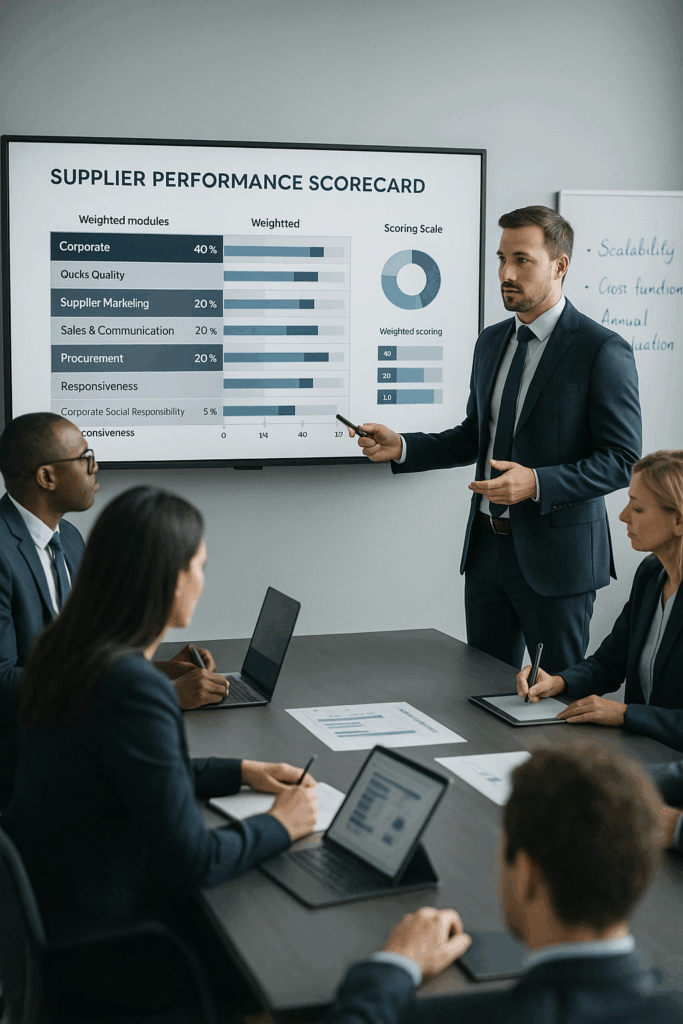

Implementation of a Holistic Supplier Performance Scorecard

1. Scoring Structure including

- Corporate

- Technical Marketing

- Sales

- Procurement

2. Methodology

- 20+ criteria

- Weighting based on relevance

- Cross-functional evaluation

- Scalable

- Reviewed annually

Results & Actions (Example Supplier)

Scorecard Results

- Overall Score: ~80%

- Strengths:

- Contract negotiation

- On-Time Delivery

- Responsiveness

- Areas for improvement:

- Quote quality

- Forecast accuracy

- Confirmation date handling

Actions

- Defined targets for quote processes

- Agreed escalation matrix

- Boosted support on promotion of technical innovation