Case Study:

Procurement Transformation

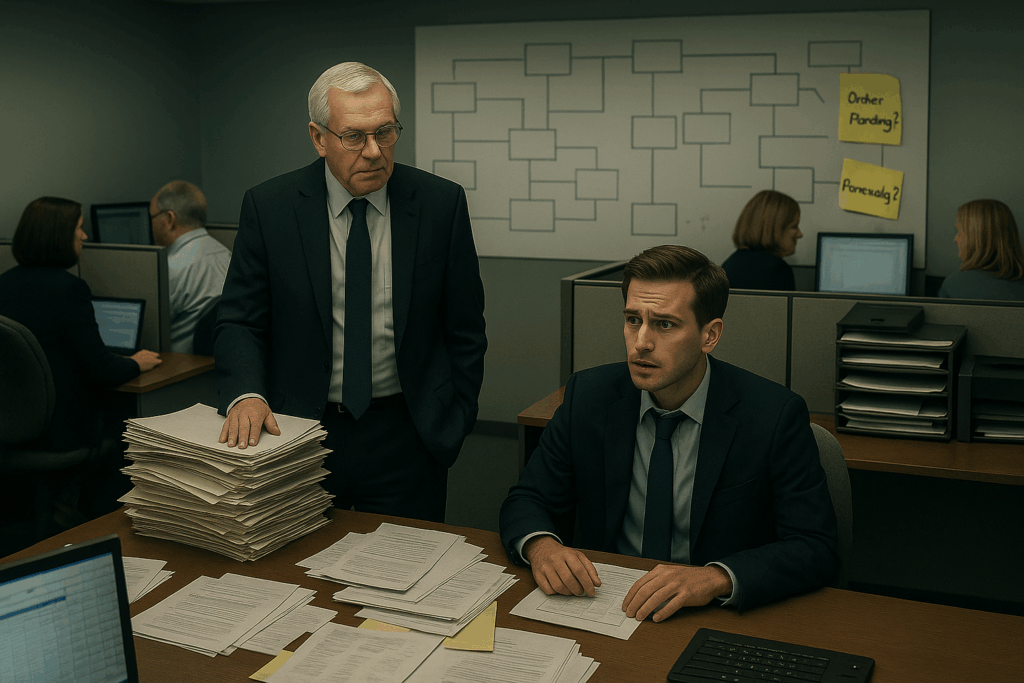

Initial Situation

- Historically grown procurement structure, fragmented across functions

- No standardized processes, roles or responsibilities

- Lack of transparency despite multi-billion euro purchasing volume

- Demographic shift created risk of knowledge loss

Actions & Approach

Execution of a transformation project

1. Vision & Organization

- Developed a company-wide Operating Model

- Structured 50+ processes

- Introduced cross-functional role models

2. Process Design & Digitization

- Harmonized key processes:

Forecast screening / Order changes / Supplier contracting & risk management

- Identified automation potential

- Built KPI-driven steering tools

3. Leadership & Change

- Empowered decentralized teams

- Clearly assigned responsibilities

- Integrated Legal, Finance & Sales

4. Execution & Culture Shift

- Multi-phase rollout (Pilot → Training → Go-Live → Coaching)

- Established ongoing review & lessons learned processes

- Positioned the department as a “Business Enabler”

Results & Impacts

- Transparency: 50+ processes clearly defined, KPI ownership established

- Efficiency: Reduced coordination overhead via defined role models

- Risk Mitigation: Early warning systems for inventory risks, supply gaps & contract issues

- Cultural Shift: True collaboration with Sales, Finance & Legal

- Sustainability: Identified and developed next-generation leadership talent